What are NPS signs?

The signs we make are digital high-pressure laminate signs (dHPL) and porcelain fired enamel signs. Both are rated for prolonged outdoor sun exposure and are popular at parks, zoos, airports, civic venues, museums and increasingly as semi-permanent architectural component signage and walls.

So how are they different?

The dHPL signs are digitally printed and laminated onto multiple layers of a substrate that is made to be vandal-resistant and weather-resistant. Based on the elaborateness of the designs, it's usually less costly to create a dHPL sign. The porcelain enamel signs often last longer but are prohibitively expensive for most short-term signage (signs which are easier to replace) needs or projects when a budget must be adhered to.

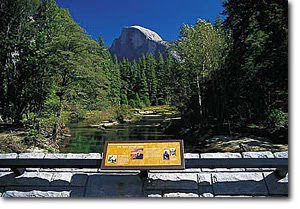

Signs shown with optional double-post mount frame and special shape cut for permanent outdoor exhibition

When the sign location will be in an unsupervised area like a campground, park or is designed for permanent (40-50-year) installations, the porcelain enamel signs are best. The porcelain signs do not fare as well in marine environs unless the sign is made with sealed edges and back to belay rusting and oxidation.

Signs shown with optional mounting hardware and special angle curved, stepped frames for permanent outdoor exhibition

In marine applications, the dHPL signs are superior in that they do not contain metals and are not subject to rusting, although they too require special treatment at the time of manufacture to offset the marine environment with a highly saline content.

Signs shown with optional angle frames for permanent outdoor exhibition

Price differences:

This is difficult to state without acknowledging the fundamental differences in printing.dHPL is a full-color digital print, laminated into a weather-resistant resin substrate and backing and is priced by the overall size, how many signs alike there will be and the overall thickness of the sign, from 1/8" to 1" thick, depending on whether the signs will be used wall-mounted, indoors or with a metal backing frame.

The Porcelain fired enamel signs are made differently, using old-fashioned photographic film sheets and one different sheet is required for each color in the sign (background, text color and any line-art graphic). There is additionally four (or more) film sheets required for full-color process photographs, as each color requires printing onto the color background enamel, then firing in a kiln-like industrial oven between each printed color and photo layer. This can take a tremendous amount of resources and labor to create but the finished effect will last for upwards of five decades.

Also impacting the final price is the overall size of the panel, any additions (cut shape, finished enameled edges, welded-on studs for mounting) and the quantity alike. Most costly is making one print, as all the same labor of creating multiple prints alike is involved in a single print. The enameled steel (porcelain) signs are made on 16ga steel.

Signs shown with optional stepped background architectural frames for permanent outdoor exhibition

Which is best for your project?

We're glad to look at your layout or idea and price these for you. As every little change in design, size, thickness, finish and quantity will affect the cost, let's work together to get this as 'finished' as possible to save the day or two in time it usually takes to get a quote put together.What kind of file do we need to send? Use this form to send artwork.

Have a finished file you want to discuss or get quoted?

That's why we're here.

We may be able to save you some cash by suggesting other options once we know the scope of your project. Let us hear from you.

Signs shown with optional angle frames for permanent outdoor exhibition

|

| Subway signs too |

If you're like us, you've run into some of these signs in you travels around the USA and other countries. Chances are we made the signs.

Contact us for more information or to set up a free email consultation.

@letterbank #PorcelainSigns #dHPLsigns #PermanentSigns #SubwaySigns

Comments

Post a Comment